Introduction

Activities that improve a building's energy performance fall into four general categories:

- enhanced O&M,

- building tune-up,

- commissioning, and

- capital projects.

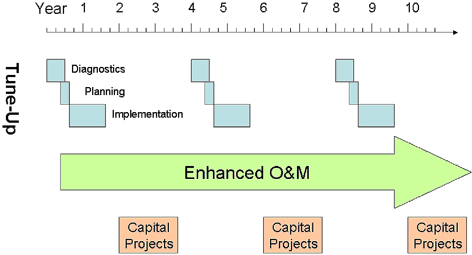

Best-Practice O&M Program discusses elements of enhanced operation and maintenance (O&M). This document describes the building tune-up process from the perspective of a building owner or operator. A building tune-up can be performed every 3 to 5 years to identify and diagnose operational problems in a building. A tune-up is less formal, less comprehensive, and less expensive than commissioning, and focuses on identifying low-cost opportunities for energy savings and other benefits. The relationship between enhanced O&M and building tune-up is illustrated below. The tune-up is periodic while enhanced O&M is an ongoing process that sustains performance improvements. Capital projects can also play an important part in building performance.

Relationship between enhanced O&M and building tune-up

Conducting a Building Tune-Up

In buildings with excessive energy use or other known operational problems, the tune-up will identify the causes of problems with the HVAC and control systems, and improve building operation-and-maintenance (O&M) practices. Most improvements require no investment beyond the tune-up cost. Two primary results of a well-executed tune-up are reduced energy use and improved tenant comfort.

A building tune-up is a periodic activity intended to fix problems and to identify cost-effective operational improvements. In a building with complex systems, a tune-up requires a systematic approach and the broad skill set of an engineering professional.

The steps in a building tune-up are:

- Assemble the project team

- Complete basic maintenance

- Review data

- Interview occupants and building engineers

- Conduct the initial on-site inspection

- Diagnose performance problems

- Make an action plan

Assemble the Project Team

Appoint the internal project team: The manager of the project team is typically the Engineering Manager or Chief Engineer. Internal team members key to the long-term success of the effort are the building operating engineers. Select engineers with recognized expertise with the building's HVAC equipment and control system.

Hire a contractor: Hiring outside specialists is strongly recommended. They will bring a fresh perspective and objectivity to the process. The in-house project manager should make it clear to the in-house team that the tune-up (or some aspect of it) is outside the scope of normal staff activities and that the contractor is being hired to provide beneficial assistance rather than find fault.

Performing a building tune-up requires a broad understanding of building control and system dynamics as well as hands-on technical ability. Sometimes a single firm can meet this need, or you can choose to hire a third-party engineering specialist to work with a service team.

Collaborate with your utility: Energy and water utilities may offer financial incentives or other professional support for conducting a building tune-up.

Complete Basic Maintenance

Before embarking on the tune-up, periodic maintenance-that is, maintenance performed at time intervals or at run-hour milestones-should be up to date. Some tune-up activities cannot be done on equipment that first requires basic periodic maintenance. For example, during the cooling season, the annual maintenance tasks for the cooling plant and systems should be completed before starting the tune-up. Typical deficiencies (dirty filters, broken or cracked belts, etc.) normally taken care of during periodic maintenance should not be left for the building tune-up to identify for repair.

Review Data

The building's excessive energy use was probably identified by reviewing utility records. As part of the scoping activity, review building performance indicators such as utility-demand-interval data or real-time, direct-digital-control (DDC) data. Set an energy benchmark and identify areas to investigate using monitoring and trend logging of key indicators of system performance.

Additionally, with team members who are not familiar with the building, review building O&M manuals and building plans to familiarize them with the layout and design of the system.

Interview Occupants and Building Engineers

The contractor should informally interview the building occupants and engineering staff. Anecdotal information on building problems and quirks provides valuable leads to pursue in the tune-up.

Conduct the Initial On-site Inspection:

The initial walkthrough by the project team will identify two types of problems:

Problems with quick fixes: easily accomplished corrections or adjustments to equipment or control system that can be done during the scoping process. Beware of "band-aid" solutions that do not address an underlying problem. If you suspect this may be the case, flag the problem for further diagnosis.

Problems with deferrable fixes: problems that require more time or investment than allowed in the walkthrough. For these, look for symptoms or known problems and flag them for further investigation in the diagnosis phase of the tune-up.

Diagnose Performance Problems

Inspect, measure, and analyze: Investigate and analyze the symptoms and problems identified in the walk through. The team will have a diagnostic plan for each item flagged for investigation. Some common HVAC problems are listed in the Symptom-Diagnosis Tool which provides a specific diagnostic procedure for each symptom.

Fix Performance Problems

Modify and adjust equipment: The inspections and associated diagnoses will lead to a list of solutions. The budget should allow some time for adjusting equipment, making minor repairs, and reprogramming controls. Other solutions may involve capital projects that fall outside the scope of the building tune-up. Many utilities have energy-efficiency programs that offer financial incentives for capital measures that reliably reduce energy use.

Make an Action Plan

The action plan should succinctly document the following project results:

Summary of equipment modifications: List what was modified or adjusted and the results, including estimates of energy and dollar savings.

Solutions identified but not implemented: List what remains to be done and include estimates of potential costs, benefits, and payback, for decision makers to follow up.

Recommendations for modifying maintenance practices: List improvements in maintenance practices that became evident during the tune-up.

Recommendations for staff training: List suggestions for areas of additional staff training that became evident during the tune-up.

Following Up

Implement the Action Plan

Evaluate action-plan recommendations and select items to implement. These may include operational adjustments, equipment modifications, or additional staff training.

Adjust operational practices. This may involve changing control sequences or equipment scheduling.

Modify maintenance procedures to reflect the best practices required to maintain the building's "tuned" performance. Change the scope of the maintenance-service contractor as necessary.

Update system documentation to reflect the changes to the O&M program.

Revise energy-performance goals. Utility bills will begin to reflect the changes made during the tune-up. Establish a new benchmark or baseline for energy performance as the new energy-consumption data becomes available.

Select potential capital projects for the organization to evaluate.

Discuss and implement revisions to staff training as indicated in the action plan. Update group and individual training plans.

Communicate the Results

Communicate the project outcome to engineering staff, executives, and the O&M leadership team. If there are more candidate buildings in your campus or portfolio, plan for additional tune-ups to build on the experience and success of this project.