Introduction

Chillers are a key component of air conditioning systems for large buildings. They produce cold water to remove heat from the air in the building. They also provide cooling for process loads such as file-server rooms and large medical imaging equipment. As with other types of air conditioning systems, most chillers extract heat from water by mechanically compressing a refrigerant.

Chillers are complex machines that are expensive to purchase and operate. A preventive and predictive maintenance program is the best protection for this valuable asset.

Learn more about establishing a Best Practice O&M Program.

Chillers commonly use more energy than any other piece of equipment in large buildings. Maintaining them well and operating them smartly can yield significant energy savings.

Types of Chillers

Mechanical Compression

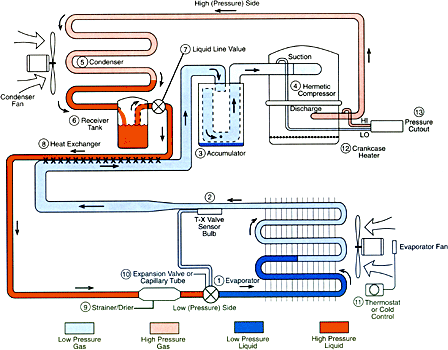

During the compression cycle, the refrigerant passes through four major components within the chiller: the evaporator, the compressor, the condenser, and a flow-metering device such as an expansion valve. The evaporator is the low-temperature (cooling) side of the system and the condenser is the high-temperature (heat-rejection) side of the system.

Mechanical Compressor Chillers

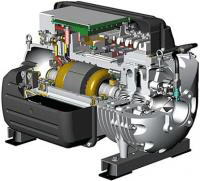

Mechanical compression chillers are classified by compressor type: reciprocating, rotary screw, centrifugal and frictionless centrifugal.

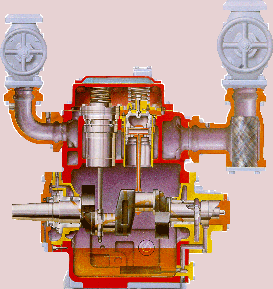

Reciprocating: Similar to a car engine with multiple pistons, a crankshaft is turned by an electric motor, the pistons compress the gas, heating it in the process. The hot gas is discharged to the condenser instead of being exhausted out a tailpipe. The pistons have intake and exhaust valves that can be opened on demand to allow the piston to idle, which reduces the chiller capacity as the demand for chilled water is reduced. This unloading allows a single compressor to provide a range of capacities to better match the system load. This is more efficient than using a hot-gas bypass to provide the same capacity variation with all pistons working. Some units use both methods, unloading pistons to a minimum number, then using hot-gas bypass to further reduce capacity stably. Capacities range from 20 to 125 tons.

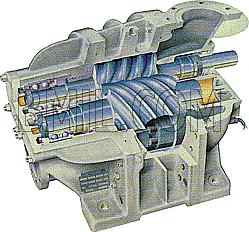

Rotary Screw: The screw or helical compressor has two mating helically grooved rotors in a stationary housing. As the helical rotors rotate, the gas is compressed by direct volume reduction between the two rotors. Capacity is controlled by a sliding inlet valve or variable-speed drive (VSD) on the motor. Capacities range from 20 to 450 tons.

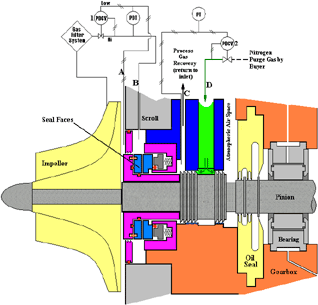

Centrifugal: The centrifugal compressor operates much like a centrifugal water pump, with an impeller compressing the refrigerant. Centrifugal chillers provide high cooling capacity with a compact design. They can be equipped with both inlet vanes and variable-speed drives to regulate control chilled water capacity control. Capacities are 150 tons and up.

Frictionless Centrifugal: This highly energy-efficient design employs magnetic bearing technology. The compressor requires no lubricant and has a variable-speed DC motor with direct-drive for the centrifugal compressor. Capacities range from 60 to 300 tons.

Absorption Chillers

Absorption chillers use a heat source such as natural gas or district steam to create a refrigeration cycle that does not use mechanical compression. Because there are few absorption machines in the Northwest U.S., this document covers only mechanical-compression chillers. You can learn more about absorption chillers at the Energy Solutions Center.

Key Components of Mechanical Compression Chillers

Evaporator

Chillers produce chilled water in the evaporator where cold refrigerant flows over the evaporator tube bundle. The refrigerant evaporates (changes into vapor) as the heat is transferred from the water to the refrigerant. The chilled water is then pumped, via the chilled-water distribution system to the building's air-handling units.

Learn more about Operation and Maintenance of HVAC Water Distribution Systems.

Learn more about Operation and Maintenance of Air Distribution Systems.

The chilled water passes through coils in the air-handler to remove heat from the air used to condition spaces throughout the building. The warm water (warmed by the heat transferred from the building ventilation air) returns to the evaporator and the cycle starts over.

Compressor

Vaporized refrigerant leaves the evaporator and travels to the compressor where it is mechanically compressed, and changed into a high-pressure, high-temperature vapor. Upon leaving the compressor, the refrigerant enters the condenser side of the chiller.

Condenser

Inside the condenser, hot refrigerant flows around the tubes containing the condenser-loop water. The heat transfers to the water, causing the refrigerant to condense into liquid form. The condenser water is pumped from the condenser bundle to the cooling tower where heat is transferred from the water to the atmosphere. The liquid refrigerant then travels to the expansion valve.

Learn more about Operation and Maintenance of Cooling Towers.

Expansion valve

The refrigerant flows into the evaporator through the expansion valve or metering device. This valve controls the rate of cooling. Once through the valve, the refrigerant expands to a lower pressure and a much lower temperature. It flows around the evaporator tubes, absorbing the heat of the chilled water that's been returned from the air handlers, completing the refrigeration cycle.

Controls

Newer chillers are controlled by sophisticated, on-board microprocessors. Chiller control systems include safety and operating controls. If the equipment malfunctions, the safety control shuts the chiller down to prevent serious damage to the machine. Operating controls allow adjustments to some chiller operating parameters. To better monitor chiller performance, the chiller control system should communicate with the facility's direct digital control (DDC).

Safety Issues

Chillers are typically located in a mechanical equipment rooms. Each type of refrigerant used in a chiller compressor has specific safety requirements for leak detection and emergency ventilation. Consult your local mechanical code or the International Mechanical Code for details.

The EPA has enacted regulations regarding the use and handling of refrigerants to comply with the Clean Air Act of 1990. All personnel working with refrigerants covered by this act must be appropriately licensed.

Best Practices for Efficient Operation

The following best practices will improve chiller performance and reduce operating costs:

Operate multiple chillers for peak efficiency: Plants with two or more chillers can save energy by matching the building loads to the most efficient combination of one or more chillers. In general, the most efficient chiller should be first one used.

Raise chilled-water temperature: An increase in the temperature of the chilled water supplied to the building's air handlers will improve its efficiency. Establish a chilled-water reset schedule. A reset schedule can typically adjust the chilled-water temperature as the outside-air temperature changes. On a centrifugal chiller, increasing the temperature of chilled water supply by 2-3°F will reduce chiller energy use 3-5%.

Reduce condenser water temperature: Reducing the temperature of the water returning from the cooling tower to the chiller condenser by 2-3°F will reduce chiller energy use 2-3%. The temperature setpoint for the water leaving the cooling tower should be as low as the chiller manufacturer will allow for water entering the condenser.

Purge air from refrigerant: Air trapped in the refrigerant loop increases pressure at the compressor discharge. This increases the work required from the compressor. Newer chillers have automatic air purgers that have run-time meters. Daily or weekly tracking of run time will show if a leak has developed that permits air to enter the system.

Optimize free cooling: If your system has a chiller bypass and heat exchanger, known as a water-side economizer, it should be used to serve process loads during the winter season. The water-side economizer produces chilled water without running the chiller. Condenser water circulates through the cooling tower to reject heat, and then goes to a heat exchanger (bypassing the chiller) where the water is cooled sufficiently to meet the cooling loads.

Verify Performance of hot-gas bypass and unloader: These are most commonly found on reciprocating compressors to control capacity. Make sure they operate properly.

Maintain refrigerant level: To maintain a chiller's efficiency, check the refrigerant sight-glass and the superheat and subcooling temperature readings, and compare them to the manufacturer's requirements. Both low-level and high-level refrigerant conditions can be detected this way. Either condition reduces a chiller's capacity and efficiency.

Maintain a daily log: Chiller O&M best practices begin with maintaining a daily log of temperatures, fluid levels, pressures, flow rates, and motor amperage. Taken together, these readings serve as a valuable baseline reference for operating the system and troubleshooting problems. Many newer chillers automatically save logs of these measurements in their on-board control system, which may be able to communicate directly with the DDC. Below is an example of a daily log that can be adapted for use with your chiller.

Download this table as a Word Document

Best Practices for Maintenance

Compared to a major chiller failure, a sound preventive and predictive maintenance program is a minor cost. Implementing a best-practice maintenance plan will save money over the life of the chiller and ensure longer chiller life. For more information on this topic go to Best Practice O&M Program.

Substandard operating practices frequently go unnoticed and become the accepted norm. Training personnel in both maintenance and operating practices is the best prevention. Many chiller manufacturers offer training for building operating engineers in operating and maintaining their chillers.

To effective maintain chillers, you must 1) bring the chiller to peak efficiency, and 2) maintain that peak efficiency. There are some basic steps that facilities professionals can take to make sure their chillers are being maintained properly. Below are some of the key practices.

Reduce Scale or Fouling

Failure of the heat exchanger tubes is costly and disruptive. The evaporator and condenser tube bundles collect mineral and sludge deposits from the water. Scale buildup promotes corrosion that can lead to the failure of the tube wall. Scale buildup also insulates the tubes in the heat exchanger reducing the efficiency of the chiller. There are two main preventive actions:

Checking water treatment: Checking the water treatment of the condenser-water open loop weekly will reduce the frequency of condenser tube cleaning and the possibility of a tube failure.

Learn more about Operation and Maintenance of Cooling Towers.

Checking the water treatment of the chilled-water closed loop monthly will reduce the frequency of evaporator tube cleaning and the possibility of a tube failure.

Learn more about Operation and Maintenance of HVAC Water Distribution Systems.

Inspecting and cleaning tubes: The tubes in the evaporator and condenser bundles should be inspected once a year, typically when the chiller is taken offline for winterizing. Alternately, for systems that operate all year to meet process loads, tube scaling and fouling can be monitored by logging pressure drop across the condenser and evaporator bundles. An increase in pressure from the inlet to the outlet of 3-4 PSI indicates a probable increase in scale or fouling requiring tube cleaning.

Inspect for Refrigerant Leaks

If possible, monitor the air-purge run timer. Excessive or increased air-purge time may indicate a refrigerant leak. If an air-purge device is not installed, bubbles in the refrigerant sight-glass may also indicate refrigerant leak. Gas analyzers can also be used to identify refrigerant leaks.

The table below provides a checklist for maintenance tasks.

Download this table as a Word document

Maintenance Schedule for Chillers

| Description | Comments | Maintenance Frequency |

|---|---|---|

| Fill out daily log | Check all setpoints for proper setting and function. Make sure there are no unusual sounds and the space temperature is acceptable. | Daily (4x) |

| Chiller use/sequencing | Turn off or sequence unnecessary chillers | Daily |

| Check chilled water reset settings and function | Check settings for approved sequence of operation at the beginning of each cooling season | Annually |

| Check chiller lockout setpoint | Check settings for approved sequence of operation at the beginning of each cooling season | Annually |

| Clean evaporator and condenser tubes | Indicated when pressure drop across the barrel (tube bundle) exceeds manufacturer's recommendations, but at least annually. | Annually |

| Verify motor amperage load limit | Motor amperage should not exceed manufacturer's specification | Annually |

| Compressor motor and assembly | Conduct vibration analysis: Check all alignments to specifications. Check all seals. Lubricate where necessary. | Annually |

| Compressor oil system | Perform analysis on oil and filter. Change if necessary. Check oil pump and seals Check oil heater and thermostat Check all strainers, valves, etc. | Annually |

| Electrical connections | Check all electrical connections and terminals for full contact and tightness | Annually |

| Check refrigerant condition | Add refrigerant if low. Record amounts and address leakage problems. | Annually |

| Check for condenser and evaporator tube corrosion and clean as needed. | Indications include: poor water quality, excessive fouling, and age of chiller. Eddy current testing may be done to assess tube condition. | As needed |

References

FEMP 2004. O&M Best Practices Guide 2.0.

FEMP 2002. Continuous Commissioning Guidebook for Federal Energy Managers.